Engineering and Manufacturing of Non-Standard Thermocouples

Development of Special Thermocouples for Demanding Industrial Processes

There are industrial processes that cannot be solved with a standard thermocouple. These are applications where temperature, atmosphere, vibration, or thermal cycles exceed the limits of conventional thermocouples.

In these cases, simply adapting a standard model is not enough. A specific solution needs to be developed.

At Jemar Termometría, we specialize in the development and manufacturing of non-standard thermocouples, designed from scratch for demanding industrial processes. We maintain complete project control, from technical conception and structural design to final manufacturing and plant validation.

Technical Design from Scratch: When the Standard Is Not Enough

We analyze the actual operating conditions to define the complete sensor architecture:

- Actual operating temperature range

- atmospheric composition and chemical aggressiveness

- Mechanical stress and structural vibration

- Thermal cycle regime

- Metrological stability required

Based on this analysis, we developed specific configurations that may include:

- Selection of the thermocouple type best suited to the actual thermal behavior

- Design of pods with non-standard materials and thicknesses

- Specific geometries for resistance to thermal fatigue and vibration

- Internal configurations optimized for long-term stability

- Fixing and protection systems adapted to each installation

We don't modify catalog models. We don't force the process to a generic solution.

We develop and manufacture the configuration that the process requires.

Real-World Cases of Non-Standard Development

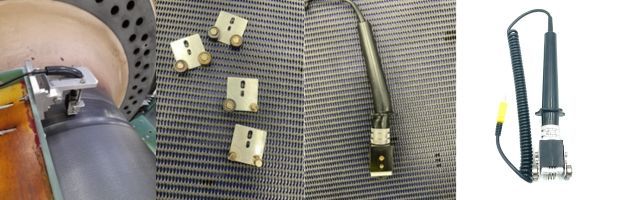

Real Case 1 – Structural redesign for application with high thermal mass and continuous movement

The problem

A customer was using a standard wheeled thermocouple to monitor the temperature of large shafts during an induction heating process.

After only two work cycles, the ensemble presented:

- Deformation due to thermal effect

- Partial fusion of components

- Loss of three wheels

The thermocouple was not suitable for the actual working conditions.

What was really happening

The process wasn't simply "370 °C".

The thermal cycle consisted of:

- Gradual heating up to 370 °C

- Extended maintenance (up to 6 hours)

- Total cycle duration: 12 hours

- Slow subsequent cooling

- Minimum 2-day break between cycles

Besides:

- The heated shaft had a large thermal mass

- The assembly remained in continuous contact with that hot mass

- The roller was constantly rotating.

- There was prolonged thermal radiation

The problem wasn't a temperature spike. It was a combination of:

- Many hours of exposure

- Heat accumulation

- Continuous movement

- Insufficient structural design for that environment

Engineering intervention

After analyzing the entire process, it was determined that the failure was not in the sensor element, but in the mechanical structure of the standard assembly.

A new, specific configuration was developed with:

- Structure entirely manufactured in AISI 316 stainless steel

- Structural reinforcement of the support

- Redesign of the fastening system

- Improved resistance to prolonged thermal radiation

- Adaptation of the assembly to continuous work with hot dough

The thermocouple was not replaced with another standard model. The entire architecture was redesigned to suit the actual process. The structural redesign transformed a standard solution into a custom configuration capable of withstanding prolonged thermal exposure and continuous operation while in motion.

Result

The new configuration allowed:

- Eliminate structural deformations

- Maintain stability during complete 12-hour cycles

- Improve mechanical resistance in continuous motion

- Ensure reliable operation in prolonged contact with hot mass

Technical conclusion

In this case, the problem was not the nominal temperature.

It was the exposure time, the accumulated thermal mass, and the constant movement.

When the standard design does not take these variables into account, the solution is not to change the model.

The solution is to redesign.

Real Case 2 – Optimization of pyrometric rod in aluminum foundry

Initial situation

A customer in the aluminum foundry sector requested a quote for a 90° K-type pyrometric rod, equipped with a Ø28 mm NSiC ceramic sleeve.

During the consultation, he raised a critical issue for his process:

What is the estimated lifespan of this pyrometric rod?

Engineering requested that a sample in use be sent to analyze the internal configuration and properly evaluate the actual working conditions.

The client sent a unit with the intention that it be replicated exactly.

Technical analysis performed

Upon receiving the sample in the workshop, the following configuration was observed:

- Type K thermocouple with Inconel 600 sheath

- Standard thread

- Ø28 mm NSiC ceramic sheath

The configuration wasn't incorrect. However, for the actual working conditions in aluminum foundries, there was room for improvement.

This type of application involves demanding factors:

- Repetitive thermal shock

- Aggressive atmosphere

- Aluminum projection

- Continuous thermal fatigue

The limitation was not only in the type of thermocouple, but also in the overall robustness of the assembly and in the ceramic protection used.

Engineering proposal

Instead of replicating the sample, a technical optimization of the design was proposed:

- Replacement of the wire with Ø2.5 mm wire for greater mechanical resistance

- Incorporation of ceramic beads to improve internal structural stability

- Replacement of the Ø28 mm NSiC ceramic sleeve with a Ø50 mm silicon carbide sleeve

The increase in diameter and the change in material improved significantly:

- Mechanical resistance

- Protection against projectiles

- Behavior under thermal shock

- Durability in a foundry environment

The requested model was not changed. The internal and external configuration was optimized to adapt it to the actual work environment.

Operational result

The new configuration allowed:

- Increase lifespan by more than 45%

- Reduce the frequency of replacement

- Improve the stability of the assembly under casting conditions

- Reduce the operating costs associated with replacement

Technical conclusion

In casting applications, copying a sample does not always guarantee the best performance.

Analyzing the internal configuration and ceramic protection allows for a significant improvement in durability without altering the functionality of the sensor.

The difference is not only in the type of thermocouple.

It's in the engineering criteria applied to the design.

In-house manufacturing with comprehensive project control

The ability to manufacture in-house is what allows us to undertake non-standard developments with technical guarantees.

We control all phases:

- Structural design of the sensor

- Selection and verification of materials

- Assembly and sealing processes

- Dimensional control and final verification

- Technical validation under real operating conditions

We work under strict criteria of quality, traceability and confidentiality, collaborating with factories, engineering firms and technical departments that require specific thermal solutions.

Optimization of Useful Life and Stability in Critical Environments

Many failures in industrial thermocouples are not due to the type of alloy, but to an unsuitable configuration for the real environment.

A specific technical development allows:

- Reduce thermal drift

- Minimize mechanical fatigue

- Improve resistance to oxidation and corrosion

- Significantly increase lifespan

- Reduce costs associated with unplanned downtime

An optimized thermocouple doesn't just measure temperature. It stabilizes the process.

Do you need a thermocouple that doesn't exist on the market?

When the industrial process requires a solution that is not available in the catalog, engineering must take over the design.

At Jemar Termometría we develop and manufacture non-standard configurations with complete process control, from technical conception and structural design to final manufacturing and validation in the plant.

When the standard stops working, we develop what's needed.

Technical Questions about Non-Standard Thermocouples

What is a non-standard thermocouple?

It is a sensor designed specifically for a particular industrial process, with customized configuration in terms of alloy type, protective material, geometry and internal structure.

When is it necessary to develop a thermocouple from scratch?

When standard models exhibit premature failures, thermal drift, mechanical breakage, or insufficient lifespan under high temperature, vibration, or aggressive atmospheres.

How can the lifespan of a thermocouple be increased?

By correctly selecting the alloy, optimizing the material and thickness of the sheath, designing vibration protection, and ensuring proper installation for the real environment.

When the standard does not offer the necessary reliability, it is time to review the configuration.

Our engineering team analyzes the actual conditions of your process —temperature, atmosphere, thermal cycles and mechanical requirements— to develop a specific solution.

Contact our technical department and we will study your application.